Steel structure engineering inspection: ensuring engineering safety and avoiding risks

Add time:

2023/08/13 23:46

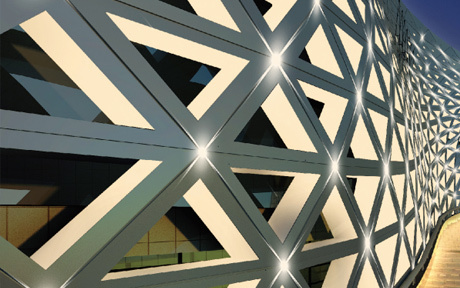

Steel structure engineering inspection: To ensure engineering and avoid risks, have you ever thought that when you walk into a high-rise building and face the magnificent steel structure, will you consider its performance and quality? The inspection of steel structure engineering is to ensure the safety of the project and avoid potential risks. In this article, we will explore the importance of engineering quality inspection for steel structure engineering and answer some common questions about engineering quality inspection. Quality inspection of steel structure engineering is a key process that ensures the quality and reliability of steel structure engineering. Professional personnel responsible for engineering quality testing conduct various inspections and evaluations of steel structures using advanced testing equipment and technology. These tests include material testing, welding joint testing, structural stability testing, etc. By promptly identifying and resolving potential problems, engineering quality inspection can effectively prevent the occurrence of engineering quality accidents. Engineering quality inspection is not only to meet requirements, but also to ensure the economic benefits of the project. When the quality of the project does not meet the standards, it may lead to an increase in future maintenance and repair costs, and may even lead to the reconstruction of the project. Therefore, it is very necessary to conduct engineering quality inspection during the construction process, as it can help us identify and solve problems, thereby ensuring the long-term stability and sustainable development of the project. When conducting engineering quality inspection, we need to pay attention to the following aspects. The first is the quality inspection of materials. The steel used in steel structure engineering must comply with relevant standards and regulations. By testing the chemical composition and mechanical properties of materials, it can be ensured that the materials used have sufficient strength and durability. Next is the inspection of welded joints. Welded joints are the most prone to problems in steel structure engineering. By using techniques such as ultrasonic testing, defects and non conformities in joints can be detected in a timely manner. It is a stability test of the structure. The stability of a structure is directly related to the engineering performance. By using methods such as vibration testing and load testing, the stability of the structure can be evaluated and corresponding measures can be taken in a timely manner. Engineering quality inspection is not only a technical activity, but also a responsibility. As professionals in steel structure engineering testing, we need to have rich experience and professional knowledge, constantly learning and improving our skills. Only in this way can we guarantee the performance and quality of the project. In short, engineering quality inspection is crucial for steel structure engineering. It not only ensures the safety of the project, avoids potential risks, but also improves the economic benefits of the project. When conducting engineering quality inspection, we need to pay attention to the quality of materials, the quality of welded joints, and the stability of the structure. Only through inspection and evaluation can we ensure the reliability of steel structure engineering.

More...

Disclaimer: The content is forwarded from the internet, and this website does not own or assume any legal responsibility. If you find any suspected plagiarism content on this website, please contact us to report and provide relevant evidence. Once verified, this website will immediately delete the suspected infringing content.

Contact us

Factory address: Jiefang Village, Guanghui Street, Yuhong District, Shenyang City

Official account

Mobile website