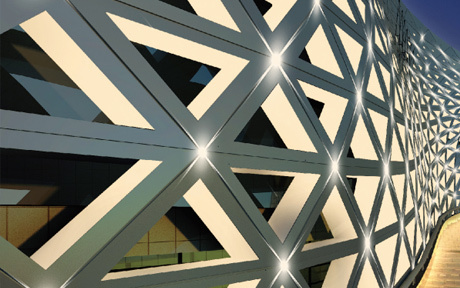

Rock wool composite panel

Keyword:

steel structure

Category:

Detail

Rock wool composite board is based on rock wool board to add cement surface, so that the rock wool board in the installation and use of the construction period shortened by 70%, effectively improve the progress of the project.

The main material of rock wool composite board is basalt wool board, basalt, iron ore, bauxite, etc. as the main raw materials, after high temperature melting and melting processing with an appropriate amount of binder made of artificial inorganic fiber, with light weight, small thermal conductivity, heat absorption, non-combustible characteristics.

Performance introduction

Rock wool composite board is on the basis of rock wool board to increase cement mortar plaster, strengthen the hardness of rock wool board, directly eliminate the process of wall plastering during construction, so that rock wool board in the installation and use of the construction period shortened by 70%, rock wool board is basalt and other natural ores as the main raw material, rock wool board by high temperature melting into fiber, add an appropriate amount of binder, curing processing and made. Rock wool board products are suitable for heat insulation and sound insulation of industrial equipment, buildings and ships.

Rock wool composite panel product characteristics

Rock wool composite slate wool characteristics

1. Appearance quality: the surface is flat, and there should be no scars, smudges and damage that hinder practicality.

2. Combustion performance: Class A non-combustible

3. Temperature resistance: 800 degrees.

4. Hygroscopicity: >200%5、Capacity: ≤1506、Oxygen index: 07、Thermal conductivity: 0.04~0.055(W/mk)

Rock wool composite board characteristics

The product is bonded and pressurized, trimmed, grooved and blanking in the process to form a groove composite board, which has good integrity, high rigidity and mechanical properties of impact resistance and shear resistance, as well as the characteristics of heat preservation, heat insulation, sound insulation and moisture resistance. Its plate length is not limited, up to more than 12 meters, which fully meets the fire protection requirements of the technical design. And overcome the previous plate does not have enough integrity and stiffness, flexural resistance and impact resistance of poor defects. Color steel rock wool sandwich composite panel: It is a new type of building material with colored steel plate as the surface layer and rock wool, fireproof and flame retardant thermal insulation materials as the core layer. It has obvious advantages such as light weight, good heat insulation, good sound absorption and sealing storage, convenient construction, short cycle, low comprehensive cost, bending resistance, corrosion, and beautiful appearance. Quality features: 1) thermal insulation, thermal conductivity: 0.035W/M.K. (2) High strength, can be used as enclosure structure, load-bearing structure, bending and compressive resistance, general houses do not use beams and columns. (3) The color is bright and does not require surface decoration. (4) Flexible and fast installation, the construction period can be shortened by more than 40%.

Rock wool composite board application field

Widely used in steel structure workshop, simple mobile room roof, wall, air clean room ceiling and partition. Product features: color steel rock wool composite board products are A grade fireproof board

1. Good fire performance: rock wool is an inner core layer or glass fiber, but any fire level requirements;

2. Color steel rock wool composite board thermal insulation: thermal conductivity λ≤ rock wool 0.044w/m.k thermal conductivity λ≤ glass wool 0.031/m.k; 3. Color steel rock wool composite board bright color: no surface decoration is required, the retention period of the anti-corrosion layer of the color steel plate is 10-15 years, and the anti-corrosion layer of the color galvanized plate is maintained for 30-45 years; 4. Color steel rock wool composite plate bending and compression, high bearing capacity: it can be used as a protective structure and a load-bearing structure, and the general house does not use beams and columns;

4. Color steel rock wool composite board bending and compression resistance, high bearing capacity:

It can be used as a protective structure and a load-bearing structure, and the general house does not use beams and columns;

5. Flexible installation of color steel rock wool composite panel:

The width of the sandwich panel is 950 type 1150 type, the surface layer can be pressed ribs and no ribs, the length can be produced according to the length required by the user, the construction period is short, and the comprehensive cost is low;

6. Scope of application of color steel rock wool composite panel:

Purification engineering, shipbuilding, food, air conditioning, workshop, boiler room, floor, activity room, cold storage, warehouse, office partition, sound insulation, etc.

inquiry

Contact us

Factory address: Jiefang Village, Guanghui Street, Yuhong District, Shenyang City

Official account

Mobile website