Detail

The full name of polyurethane is polyurethane, which is a collective term for macromolecular compounds containing repeating urethane groups on the main chain. It is made by the addition of organic diisocyanates or polyisocyanates with dihydroxy or polyhydroxy compounds.

Polyurethane foam is widely used.

Polyurethane elastomers can have high elasticity and strength, excellent wear resistance, oil resistance, fatigue resistance and vibration resistance in a wide hardness range, and are known as "wear-resistant rubber". Although the output of polyurethane elastomer in polyurethane products is small, polyurethane elastomer has excellent comprehensive properties and has been widely used in metallurgy, petroleum, automobile, mineral processing, water conservancy, textile, printing, medical, sports, grain processing, construction and other industrial sectors.

PU is polyurethane, and PU skin is the skin of polyurethane components. This material is widely used in clothing manufacturers to produce clothing, commonly known as imitation leather clothing. PU is the abbreviation of English polyurethane, the chemical Chinese name polyurethane its quality is also good or bad, good bags mostly use imported PU leather;

Polyurethane composite panels

Polyurethane composite panels are also called PU sandwich panels.

The composite board with polyurethane as the core material is composed of upper and lower layers of color steel plate plus intermediate foamed polyurethane, using the world's advanced six-component online automatic operation mixing pouring technology, which can complete the ratio mixing process of the social batching center or factory at one time online, and can be adjusted at will according to the temperature, so as to produce a unique high-strength, energy-saving, green and environmentally friendly building board.

Because of its good fire and moisture resistance, it is also commonly used in other materials of composite board edge banding core material, polyurethane edge banding composite board using high-quality color coated steel plate as the surface material, continuous rock wool, glass wool as the core material, high-density rigid foamed polyurethane for groove filling, after high-pressure foaming curing, automatic dense cloth cotton and by ultra-long double tape control molding composite, compared with the traditional hanging cotton maintenance material, fireproof, thermal insulation effect is better, more durable performance, convenient installation, elegant appearance. It is a leader in steel building maintenance materials.

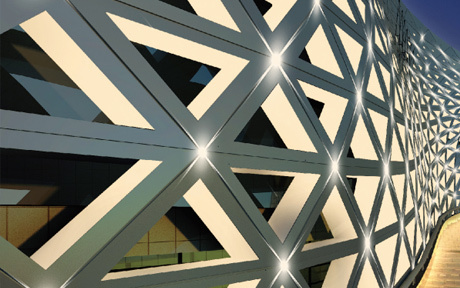

Generally used for the roof outer panel of the building, the board has good heat preservation, heat insulation, sound insulation effect, and polyurethane does not fuel combustion, in line with fire safety. The joint action of upper and lower plates plus polyurethane has high strength and rigidity, and the lower board is smooth and flat, with clear lines, which increases indoor aesthetics and flatness. Easy installation, short construction period, beautiful appearance, is a new type of building material.

This sandwich panel has lightweight, beautiful and good anti-corrosion performance, and can be directly processed, it provides a new type of raw material for the construction industry, shipbuilding industry, vehicle manufacturing industry, furniture industry, electrical industry, etc., and plays a good effect of replacing wood with steel, efficient construction, energy saving, and pollution prevention.

inquiry

Contact us

Factory address: Jiefang Village, Guanghui Street, Yuhong District, Shenyang City

Official account

Mobile website